December 16, 2020

The sensor produces a near IR frequency depth image using iToF technology. Developed in the last 18 months together with the Chinese Opix and a smartphone manufacturer that plans to integrate it with a 3D camera for the phones it produces

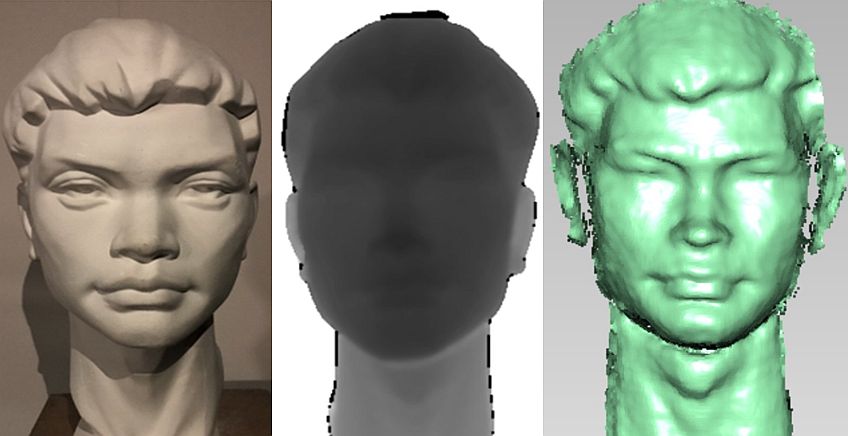

Tower Company from Migdal HaEmek (Tower Semiconductor) Has been able to produce a sensor for a 3D camera designed for use in smartphones for applications such as face recognition, and other applications that rely on distance measurements and obtaining a 3D image of the environment or of photographed objects. The sensor makes it possible to produce a three-dimensional image of the face at a resolution of 640 by 480 pixels. The project was conducted in collaboration with the Chinese company Pebbles Opix And with a large smartphone maker, which will integrate it into the phones it manufactures.

The two main methods for performing 3D measurements are the stereoscopic method and the single sensor method. The stereoscopic method is similar to the human eye: two sensors located next to each other photograph a particular object, and then calculate the distances of the different points in the space of the differences between the corresponding pixels in the different sensors (triangulation).

The second way is through an active single sensor. An energy source sends a light pulse which is reflected back to the sensor and the time difference is used to calculate the distance of each point in the image. This is the Time of Flight method. The ToF method is also divided into two parallel approaches: direct measurement and indirect measurement (Indirect Time of Flight), or iTOF for short. In the direct method, the time difference between the transmitted pulse and the repeating pulse is measured, and in the indirect method, the difference between the show (phase) between them is measured. In both cases the light source is a diode that emits infrared light (IR).

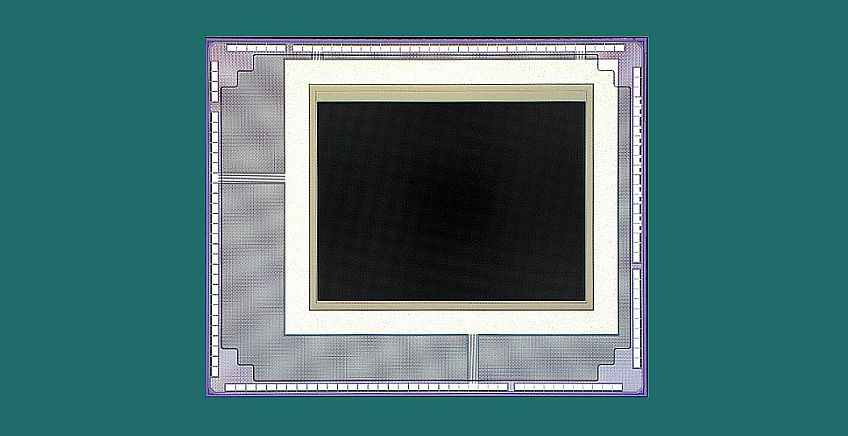

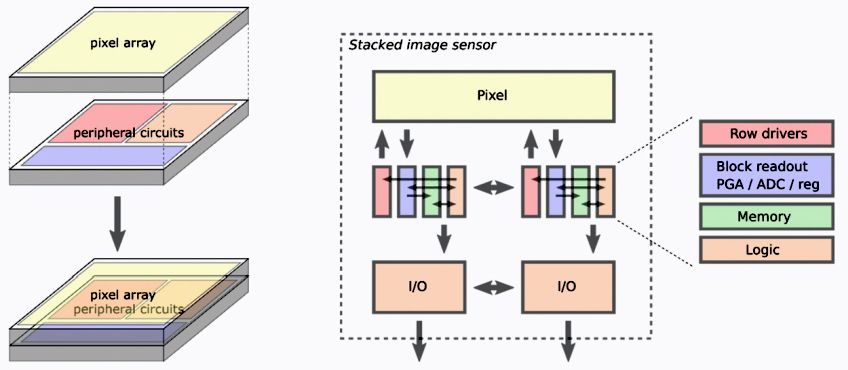

Tower and Ofix said it was an iTOF sensor that works using a near-infrared (NIR) radiation source. The advantage of using this frequency lies in the fact that it is both invisible and safe to use and has no danger of impairing the sense of sight. The sensor is produced in a tower stacked BSI CIS process used to produce CMOS-based image sensors with a geometry of 65 nm.

The sensors are manufactured at a tower plant in the city of Ozu, Japan. The first prototype features 5-micron pixels at 640 by 480 pixels and a MIPI CSI-2 communication interface, which is the most common camera interface in the field of mobile accessories. Tower said its manufacturing process allows for fast modulation of signals up to 165MHz, allowing up to 30 depth images per second.

Ophix CEO Xinyang Wong has revealed that the joint work has been done over the past 18 months. Ophix Shenzhen focuses on developing CMOS sensors for 3D cameras. , And are then connected one on top of the other (see image below) .This method allows easy making of changes and updates in each of the sensor layers.

Posted in categories: Optoelectronics, News, Semiconductors, Israeli Industry

Posted in tags: 3D, CMOS sensor, Tower semiconductor