The research, by an international team from the Autonomous University of Madrid and the Technical University of Denmark, used 3D printing to create scaffolds for engineered flat brain organoids.

The scaffolds allowed a large increase in brain organoid size and after 20 days, a self-generated fold was observed. Their findings are published in the journal IOP Publishing Biofabrication.

The work aims to address a number of the deficiencies of existing brain organoids. One of the lead authors, Theresa Rothenbücher, said: “Lack of vasculation leads to release limits for nutrients and oxygen, leading to necrotic tightness for organoids larger than about 500 μm.

In an attempt to solve this problem, brain organoids are heavily mobilized. While the inclusion of endothelial cells in the culture system increases the complexity of the model, the generated vascular structures show no activity (blood flow) in vitro. We are able to get around this issue by using bioengineering techniques. “

By inoculating brain organoids with polycaprolactone scaffold (PCL), we were able to change the shape to a smooth morphology. Flat Brain Organoids (efBOs) have beneficial release conditions so their material is better supplied with oxygen and nutrients, preventing the formation of necrotic tight junctions. “

Hakan Gürbüz, Lead study author

The transition from spherical to horizontal shape leads to a significant increase in the size and surface-to-size ratio of the brain organs. ”EFBOs also offer greater potential for the creation of biologically relevant systems. , due to the complexity of the modules they enable .. Ensuring the long-term viability of these models is a key objective of this research branch, which has been difficult to reach. this: horizontal organoids treat a lifelong problem by avoiding the formation of necrotic tissue.

“3D printing of scaffolds was crucial in overcoming the shape boundaries of previous spherical models. Contributor author Jenny Emneus says, 3D printing enables:” Material reproduction of unique 3D scaffolds with architectural complexity, precision and design flexibility. By incorporating a 3D printed scaffold into the culture protocol, the size of the brain organs and the density and thickness of the pile can be adjusted. “

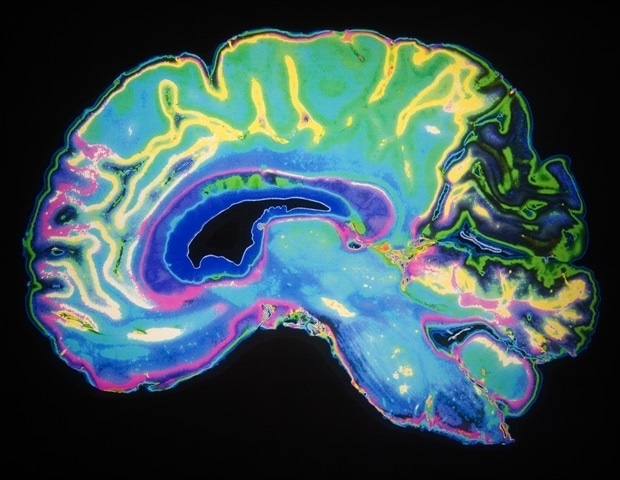

The resulting model showed a consistent formation of a neuroepithelial layer similar to gyrification. The author added Alberto Martinez-Serrano said: “… we were able to observe a fold reminding us of gyrification around day 20, which was self – generated by the tension.

To our knowledge, this is the first study to report that gyrification is closely induced in neuronal tissue in vitro. ”The appearance of gyrification indicates another increase in the surface area and is similar to the human brain development process. .

Although brain organoids do not generate true human brain anatomy, they are an important step towards rebalancing the human brain; print-like models such as these organs may replace the use of animal models in research on drug screening for toxicity and understanding of disease progression.

Alberto Martinez-Serrano continued: “The human brain is the most complex organ of the body and because of its accessibility, we do not yet have scientific knowledge about brain development and disease. Animal studies are limited to ethical and should be minimized.

Especially for drug screening applications, a highly reproducible protocol with simple measures of print culture and consistent production is required. We consider our efBO protocol as the next step toward creating a stable and reliable human brain model for drug screening applications and spatial patterning tests. “

Source:

Magazine Reference:

Rothenbücher, TSP, et al. (2021) Next-generation human brain models: engineered horizontal brain organoids by gyrification. Biofabrication. doi.org/10.1088/1758-5090/abc95e.