With the rise of COVID-19 globally, researchers are duplicating ways to develop diverse non-chemical technologies that may be effective in killing viruses, but without harm to humans and the environment.

A recent study by the KAIST research team will be one of the responses to these efforts. Professor Seung Seob Lee and Dr. Ji-hun Jeong from the Department of Mechanical Engineering developed a harmless air sterilization prototype incorporating electrosprayed water from a polymer micro-nozzle range. This study is one of the projects supported by the KAIST New Design R&D Initiative in response to COVID-19. Their study was reported in Polymer.

The electrosprayed microdroplets contain reactive oxygen species such as hydroxyl radicals, superoxides known to have antimicrobial action. The circulation extends the sex life of reactive oxygen species, which enables the droplets to perform their microbial action effectively. Preliminary research has already confirmed the non-chemical effects and encapsulation of electrosprayed droplets.

Despite its potential for non-chemical applications, electrosprayed water typically operates under the condition of electrical transmission, which can generate ozone. Inhalation of ozone is known to cause damage to the respiratory system of humans. Another technical obstacle to electrospraying is the low flow rate problem. Since electrospraying exhibits a droplet size dependence on the flow rate, there is a limitation for the number of water microdroplets that a single nozzle can produce.

With this in mind, the research team developed a series of dielectric polymer micro-nozzles to perform complex water electrospraying without electrical dissipation. The polymer micro-nozzle range was fabricated using MEMS (Micro Electro-Mechanical System) process. According to the research team, the nozzle can carry five to 19 mini-nozzles depending on the application required.

The high aspect ratio of the micro-nozzle and inward traction device has been proposed to focus the electric field at the top of the micro-nozzle, which prevents the electrical transmission caused by tension. high water surface. A series of microphones with a hydrophobic coating around the micro-nozzle was also proposed to prevent wetting of the micro-nozzle area.

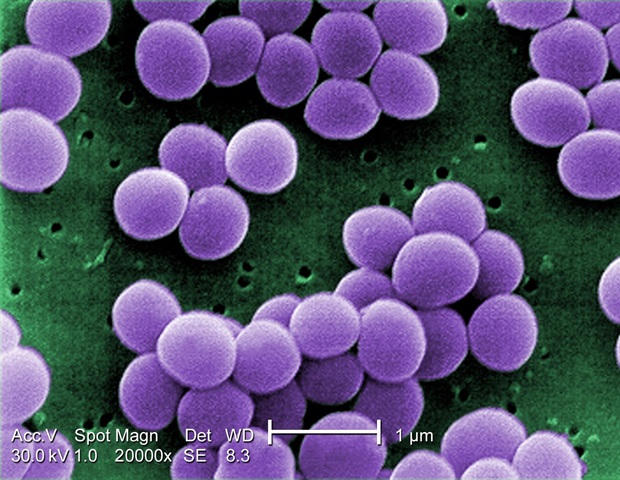

The polymer micro-nozzle range achieved in a conventional jet cone mode without electrical dissipation as demonstrated by high-speed imaging and nanosecond pulsed imaging. The water microdroplets were measured to be in the range of six to 10 μm and exhibited antimicrobial effects on Escherichia coli and Staphylococcus aureus.

We believe that this research can be applied to air-conditioning products in areas that require non-chemical and humidification activities. “

Seung Seob Lee, Professor, Department of Mechanical Engineering, Korea Institute of Advanced Science and Technology

Source:

Korea Institute of Advanced Science and Technology

Magazine Reference:

Jeong, JH, et al. (2020) Micro-atomizer polymer for water electrospray in cone jet mode. Polymer. doi.org/10.1016/j.polymer.2020.122405.