Space food is very deficient, but new technology is slowly changing the way astronauts eat. When the first astronauts in space burst the food from pipes like a toothpick, modern day astronauts dig for ice cream and fresh fruit, and taste the food with salt and pepper.

Space food is very deficient, but new technology is slowly changing the way astronauts eat. When the first astronauts in space burst the food from pipes like a toothpick, modern day astronauts dig for ice cream and fresh fruit, and taste the food with salt and pepper.

But there are still limits to the types of food that can withstand microgravity. Anything that can remove hooks, for example, is considered dangerous, as food grains can hit electrical systems or spacecraft air filters.

So tech companies are trying ways to grow food aboard a spaceship.

In late September, Israeli food starter Aleph Farms took a look at meat growth in space for the first time, with the help of a 3D printer. The experiment is not entirely new, but it does show that meat can be grown in a wide variety of harsh environments.

To make the meat they grow in a laboratory, Aleph Farms begins by removing cells from a cow through a small biopsy. The cells are then placed in an environmentally friendly “broth” of nutrients inside a cow’s body. From there, they grow into a thin piece of steak.

Those who have tasted the product say it leaves something you want, but it is supposed to resemble the texture and flavor of traditional beef.

“We are the only company with the capacity to produce full-text meat that includes muscle fiber and blood vessels – all the parts that provide the necessary structure and connections to tighten them,” said CEO Aleph and co-founder Didier Toubia said last year.

But to grow the meat in space, Aleph Farms had to change their process a bit.

First, they put the beef cells and feed broth in closed sieves. Next, they installed the filters on the Soyuz MS-15 spacecraft in Kazakhstan. On September 25, the spacecraft departed for the Russian section of the International Space Station, going about 250 miles away from Earth.

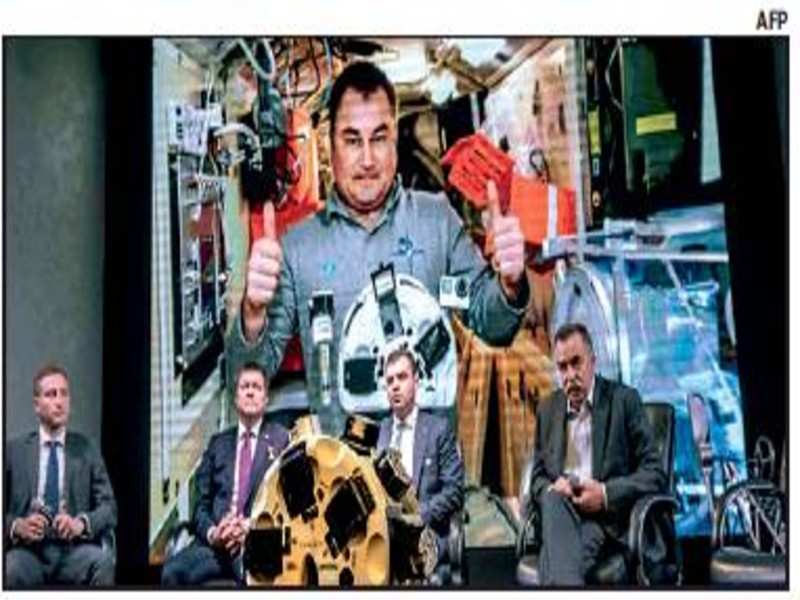

When the filters arrived at the station, Russian astronauts fitted them to a magnetic printer from the Russian company 3D Bioprinting Solutions. The printer would then reproduce the cells to make muscle material (the “flesh”). The bioprinter produced beef, rabbit and fish cloth using magnetic fields in microgravity. The samples returned to Earth on October 3rd.

“It’s one small thing for a man, one big bite for a human,” said Yusef Khesuani of 3D Bioprinting Solutions, the Russian laboratory that created the bioprinter.

This experiment is not the first time that food has been artificially grown in space. In 2015, astronauts launched romaine lettu on the ISS. Nasa is now developing a “space garden” that will bring lettuce, straw, carrots, and potatoes to the Gateway, a proposed space station that could orbit the moon. The test is an indication that meat could be grown anywhere on Earth. The ability to print meat in microgravity is not just good news for astronauts. He also suggests that meat companies could print in real environments on Earth – especially in places where water or land is scarce.

It typically takes up to 5,200 gallons of water to make one 2.2-pound steak. But cultured meat growing uses about 10 times less water and land than traditional livestock agriculture.

The need to make food while conserving natural resources is more important than ever.