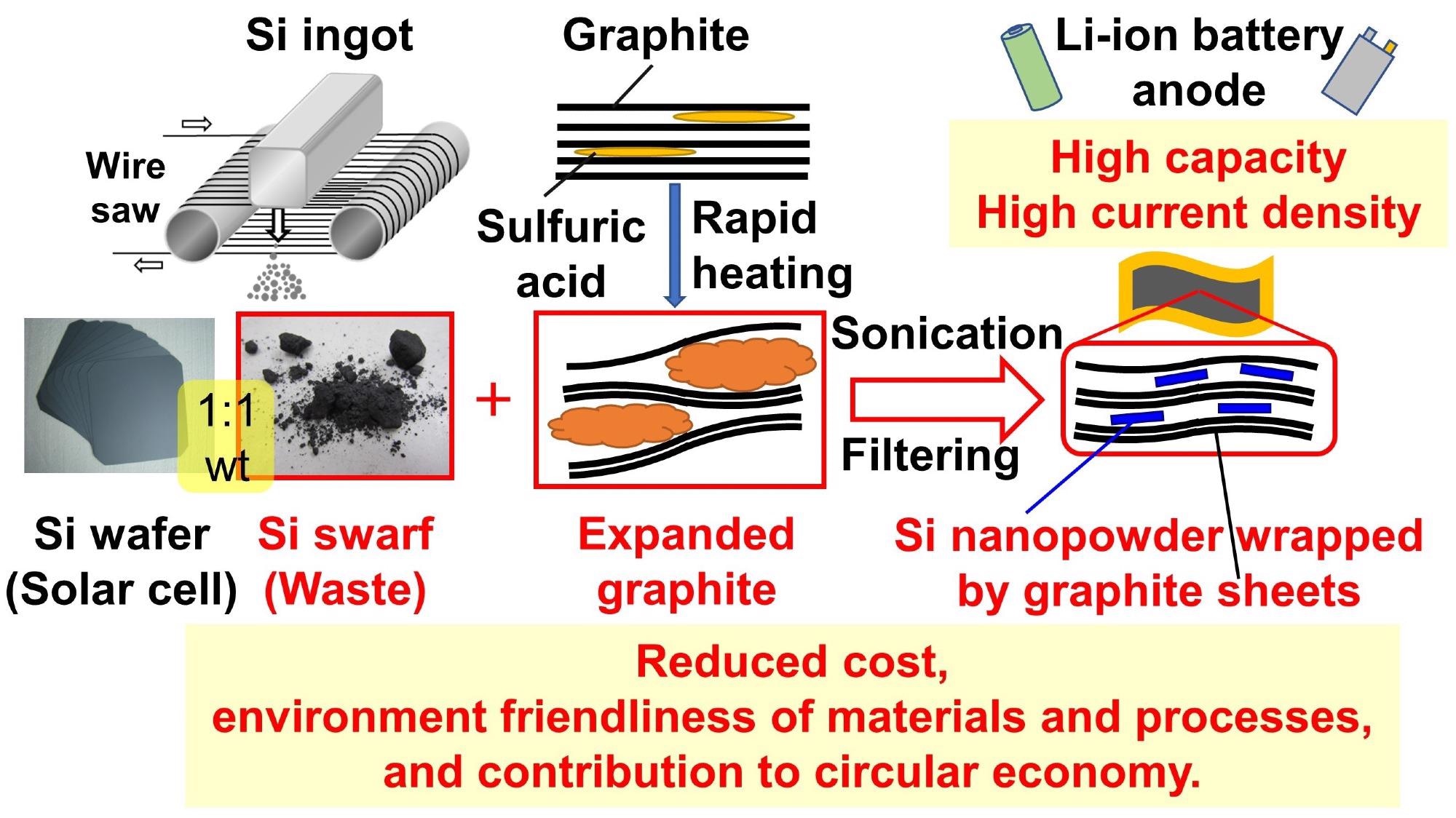

Scientists at Osaka University have created lithium-ion battery (LIB) electrodes with a silicon swarf (Si) or graphite sheet composites. This helped to achieve cost reduction, environmental friendliness, and high performance.

LIBn has been widely used in a number of mobile electronics. Recent issues of climate change and global warming have increased the demand for LIBs in the movement of solar photovoltaic output and electric vehicles.

Si was studied as an active material with a theoretical high capacity of 3578 mAh / g, which is approximately 10 times higher compared to graphite capacity (372 mAh / g).

Currently, a research team from Osaka University has employed a flake-shaped Si nanopowder coated with ultrathin graphite sheets (GSs) to form LIB electrodes with high normal density and areal capacity.

Generally seen as industrial waste, Si swarf is extracted at a rate of 100,000 tons per year worldwide from Si ing ing which is synthesized from silica through processes at 1000 ~ 1800 ° C.

Fixed grain wire saws and water-based coolers open the door to the use of Si swarf as an anode active material with high capacity at a lower price.

Nanocarbon materials were added to Si electrodes to increase cyclability and electrical conductivity. Several approaches to handling the large variation of Si electrodes at relatively high costs have already been demonstrated.

However, the Si electrodes do not exhibit all the features required for high electrical performance, in particular, environmental friendliness of materials and processes, reduced cost and round economy.

In this study, Si / graphite sheet composites from Si swarf and expanded graphite are used as the active material with lower cost and thermal budget. Si nanopowder is dispersed and folded between GSs made of expanded graphite. GS bridges are formed over cracks and eliminate cracking and peeling Si. Square GSs fold Si / GS composites, and act as stable frames that ensure electrolyte pathways and buffer locations for change in Si measurement..

Jaeyoung Choi, First Author Study, Osaka University

The Si or GS concentration structure and the delithiation constraint tend to increase the cyclability up to 901 cycles at 1200 mAh / g.

The current density and areal delithiation capacity of the Si / GS electrons increases serially to 4 mAh / cm2 and 5 mA / cm2, respectively, with the large load for more than 75 cycles, but thick electrodes with Si with a C coating are fused in C.2H.4 less competitive.

Si anode batteries with high capacity and high conventional density are capable of being used in electric vehicles. This capability, combined with more generation of Si swarf as industrial waste, will allow us to increase our greenhouse gas emissions and GDS performance.

Taketoshi Matsumoto, Corresponding Author, Osaka University

Journal Reference

Choi, J., et al. (2021) Si Swarf wrapped with graphite sheets for Li-Ion battery chargers with improved Overvoltage and Cyclability. Journal of the Electrochemical Society. doi.org/10.1149/1945-7111/abdd7e.

Source: https://www.osaka-u.ac.jp/en