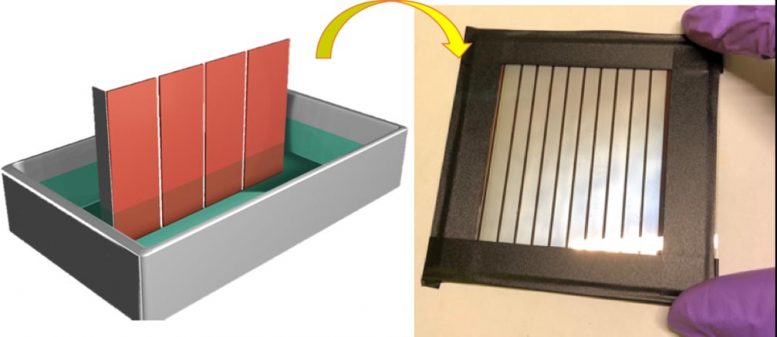

A new immersion process using sulfolane addition creates high-performance perovskite solar cells. The method is cheap and well-positioned for scaling up to a commercial product. Credit: Los Alamos National Laboratory

Sulfolane-additive process achieves easy manufacturing, low cost, high performance, long operating life.

A new, simpler solution for making sustainable perovskite solar cells overcomes the main obstacle to mass production and commercialization of this promising renewable energy technology, which has largely been -out of reach for over ten years.

“Our work is soon paving the way for large-scale low-scale commercial production of large-scale solar modules,” said Wanyi Nie, a research scientist at the Center for Integrated Nanotechnologies. Nie is the corresponding author of the paper, published on March 18, 2021, in the journal Joule. “We were able to demonstrate the approach through two small modules that have reached championship levels of converting sunlight into power with a much longer operating life. Because this process is quick and low cost, we believe it can be easily adapted to scalable manufacturing in industrial settings. ”

Highly anticipated solar technology

Perovskite photovoltaics, seen as a working competitor to the experienced silicon-based photovoltaics on the market for decades, has been an emerging technology over the past decade. Commercialization has been limited by the lack of a solution to the big challenge of the field: scaling up high-efficiency perovskite solar cell models from the mountain top to the factory floor.

The team, in collaboration with researchers from the National University of Taiwan (NTU), devised a one-step spinning coating method by adding sulfolane as an additive in the perovskite precursor, or the melting material formed by the perovskite crystal through chemical reaction. As with other manufacturing methods, this crystal is deposited on a substrate.

The new process allowed the team to produce high-performance, mass-produced photovoltaic devices that are highly efficient at generating power from sunlight. These perovskite solar cells also have a long operating life.

Through a simple immersion method, the team was able to deposit a high-quality perovskite crystalline thin film in a large functional area in two small modules, one of about 16 square centimeters and the other nearly 37 square centimeters. Making a uniform thin film over the entire width of the photovoltaic module is critical for machine performance.

Crops in power

The smaller models achieved power conversion efficiencies of 17.58% and 16.06%, respectively – among the key reported to date. Power conversion efficiency is a measure of how efficiently sunlight is converted to electricity.

For other perovskite manufacturing methods, one of the main obstacles to industrial-grade manufacturing is their narrow processing window, the length of time the film can be laid on the substrate. To obtain a uniform crystalline film that is well bonded to the underlayment, the deposition process must be tightly controlled within a few seconds.

Using sulfolane in the perovskite precursor expands the processing window from 9 seconds to 90 seconds, creating tight crystalline layers over a large area while being less dependent on the processing conditions.

The sulfolane method can be easily modified by the existing industrial manufacturing methods, which will help pave the way towards commercialization.

Perovskite is any material with a unique crystal structure similar to the mineral perovskite. Perovskites can be fabricated and fabricated into very thin films, which makes them useful for photovoltaic solar cells.

Details: “Simple one-step method with wide processing window” by Hsin-Hsiang Huang, Qi-Han Liu, Hsinhan Tsai, Shreetu Shrestha, Li-Yun Su, Po-Tuan Chen, Yu-Ting Chen, Tso-An Yang, Hsin Lu, Ching-Hsiang Chuang, King-Fu Lin, Syang-Peng Rwei, Wanyi Nie and Leeyih Wang, March 18, 2021, Joule.

DOI: 10.1016 / j.joule.2021.02.012

The funding: This work was accomplished, in part, at the Center for Integrated Nanotechnologies, a Science Office User Facility run for the U.S. Department of Energy (DOE) Science Office by Los Alamos National Laboratory (LANL) (Contract 89233218CNA000001). Work by Shreetu Shrestha and Wanyi Nie was supported by the LANL-LDRD program. Hsinhan Tsai acknowledges the financial support of J. Robert Oppenheimer (JRO) of the prestigious Postdoc Federation at LANL.